Did you know that by 2029, the metal fabrication industry will reach $29 billion?

Metal fabrication is an ever-evolving industry. It enables companies to address technological challenges and create a variety of products. From home automation to automotive and aerospace, metal fabricators play a critical role.

If you’re interested in custom metal fabrication and want to learn how to build custom products, you’re in the right place. Read on to learn about metal fabrication tools and what they are.

Basic Tools

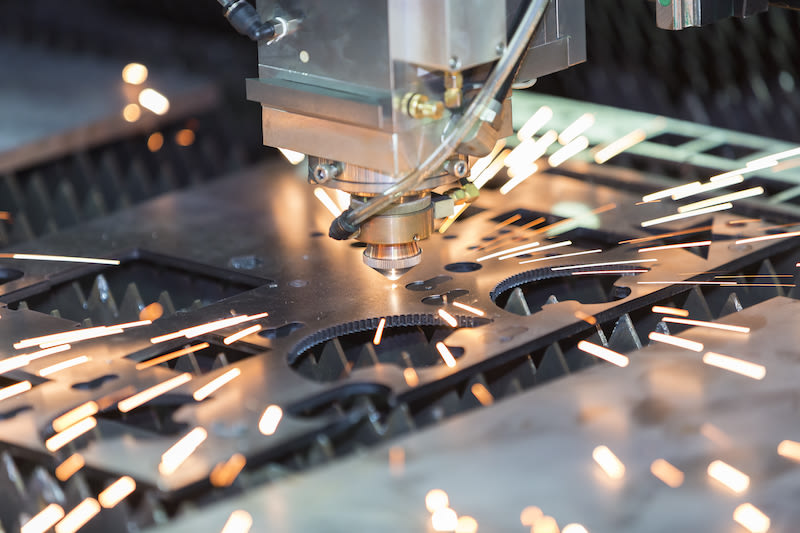

Metal fabrication is the process of cutting and manipulating different types of metal to form a specific shape for a particular use. There are some essential tools and materials that should be acquired to get started.

These include sheet metal shears, metal snips, metal saws, welding torches, hammers, drills, grinders, and clamps. Materials, metal frames, rods, gaskets, bolts, washers, and nuts are some of the basics needed. Additionally, various types of metal, such as aluminum, steel, and iron, are essential to do the necessary tasks.

Types of Metal Used in Fabrication

There are several types of metal, and it can be helpful to know the differences. The most common types of metal are aluminum, steel, and stainless steel.

Aluminum is lightweight and low in cost, making it ideal for projects that don’t need extreme strength. Steel is stronger but is susceptible to rust, making it a great choice for indoor projects.

Stainless steel is the most resistant to corrosion. It offers supreme strength, making it the best choice for outdoor use. Knowing the advantages and limitations of each metal is essential to achieving desired results.

Techniques for Successful Metal Fabrication

First, one must understand the materials and processes being used. Second, one must know the different tools available, such as a sander, welder, saw, and drill.

Third, one must also have a good sense of how the tools work together with metal. Last, familiarizing oneself with different fabrication techniques, such as cutting, forming, welding, and finishing, is imperative.

Want to learn more about metal fabrication? Check out Allied Industrial Group Fabrication now.

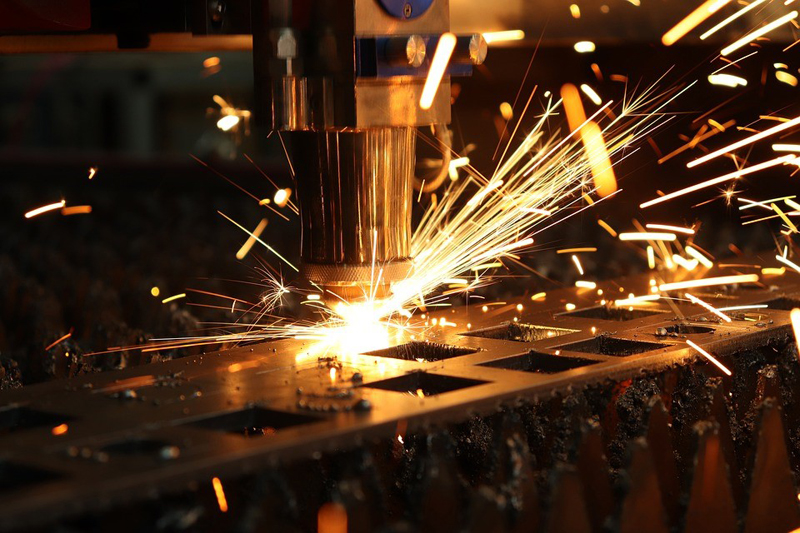

Safety Guidelines

Metal fabrication is a field full of opportunity but also hazardous. Safety guidelines must be followed to prevent injuries or other harm.

Before beginning the project, workers should take the necessary steps to protect themselves. This is for wearing proper safety gear. This includes safety glasses, welding gloves, metal files, metal chisels, and a welding helmet.

Tools should be handled with caution, as they can cause severe injury or death. Additionally, basic machinery setup and maintenance should be checked to ensure safe and secure operations.

Lastly, workers should be up-to-date on all safety regulations to stay safe in the workspace. Understanding these safety guidelines is the first step in metal fabrication safety.

Transform Your Ideas Into Reality

Metal fabrication has various tools and materials, each with its purposes and advantages. With this guide, you now know more about the elements of fabrication.

From welding to grinding and more, you can create great products. Start testing new tools and materials to find the best fit for your project and transform your ideas into reality.

Do you want to find more helpful info? Check out more of our guides on our blog today!