Recycled plastics are used plastic products or waste from several manufacturing processes that have undergone reformulation and other recycling processes. They are cheap. As a result, they are the favorite materials in industries such as the automotive industry, which needs low-cost materials.

The automotive industry works with recycled plastic using manufacturing processes such as CNC plastic machining, plastic injection molding, and 3D printing. For example, based on accuracy, many CNC prototypes and parts are made from recycled plastics. However, this article will discuss how the automotive industry uses 3D printing to manufacture prototypes and real parts from recycled plastic.

How the Automotive Industry Makes 3D Printing Material from Plastic Waste

To recycle used plastic products and waste and use 3D printing, the automotive industry uses the distributed recycling and additive manufacturing process (DRAM). The sophistication of the process depends on the automotive company, the volume of plastic waste, and the capability. Below is a summary of the general procedure:

Step 1: Collect Plastic Waste

Operators collect used plastic products or plastic wastes from manufacturing services. The properties of recycled plastic depending on the type of plastic product or the manufacturing processes that generate such waste. For example, plastic waste obtained from CNC machining is majorly brittle, chip, and low volume.

Step 2: Sort the waste

Sort the plastic product based on the type of plastic. This step is very important when working with used plastic products. Although there are many other sorting methods, using the type of plastic as a sorting method is the most ideal due to the need for uniformity.

Step 3: Grind/Shred the used plastic product or plastic waste

Grind or shred the used plastic product and waste into bits. After grinding, you can extrude the plastic bits into filaments. However, for 3D printers with a material hopper, you can feed the plastic bits directly.

Filaments made from recycled plastics have near-the-same qualities as filaments from virgin plastics. However, they cost lesser, and the automotive industry can still be profitable using them irrespective of the labor cost.

Step 4: Print the product

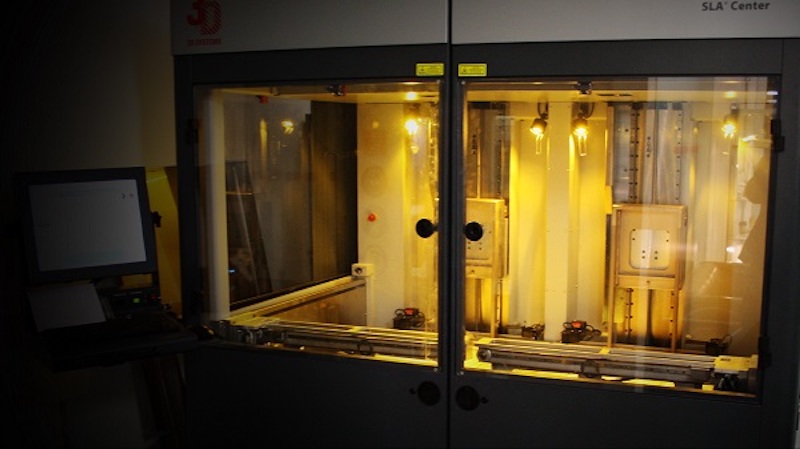

Printing the automotive part depends on the machine type and the 3D printing technology used. Nevertheless, the most common technology is FDM printing.

Common Ways, the Automotive Industry, Uses Recycled Plastic in 3D Printing

There are several ways automotive part manufacturers use recycled plastic materials in part prototyping and manufacturing. Below are the common ways car company uses recycled plastic in their car part production process.

Ford

Ford is an automotive company leading the charge on using recycled plastic in the automotive part manufacturing industry. The American car company works with a 3D printing technology company called Carbon and uses 3D printing to manufacture different automotive parts used in their vehicles

A common material favored by the two companies is the epoxy-based EPX 82, an engineering plastic material known for its durability and high strength.

Aside from epoxy-based EPX 82, Ford uses materials such as wheat, spent soy, and rice, to make parts like the carpet and undercarriage.

In collaboration with Carbon, Ford makes several automotive parts using over a billion recycled plastic bottles. According to automotive and vehicle giants, recycled plastic helps improve power consumption and reduce noise in their automobiles.

Volvo

Volvo is another car company that uses recycled plastic. They have an aggressive approach towards using recycled plastic, so much they earned the United Nations praise.

According to Volvo, they have a projection that from 2025, recycled plastic will make up 25% of all plastics utilized in making their automobiles. Such plastics will come from used plastic products such as fishing nets and old bottles, and they will be applicable in making car carpets and dashboards.

Furthermore, Volvo goes a step further in using recycled plastic for 3D printing parts as they incorporate other materials into the plastic. As a result, they boost the plastic material’s properties and qualities, further making it suitable for automotive car part manufacturing.

Nissan

Nissan also uses plastic fiber from plastic bottles to make several vehicular components, such as the sound insulation layers in their dashboards. Furthermore, they recycle their bumpers to make new bumpers.

A common example of a vehicle made by the car manufacturer is the Nissan Leaf, made from 25% recycled materials. This includes recycled plastics for the seats and recycled fabric for the pads. As a result, it is a very eco-friendly vehicle

Toyota

Toyota is another car company that favors using recycled plastic in its automobile manufacturing process. While they might not be proactive like Volvo and Ford, they are catching up. For example, they used bioplastic materials in making car components used in vehicles such as Toyota’s Prius, Kia’s Soul EV, and Jeep Grand Cherokee.

Effect of using recycled plastics

The use of recycled plastic has a lot of impact on the environment and industry. Below are a few reasons why automotive car parts manufacturers. Below are a few impacts of using recycled plastic

Reduction in plastic waste

One major impact of the use of recycled plastic by the automotive industry is the reduction in environmental pollution due to plastics. The automotive industry uses a large volume of plastic, drastically reducing plastic. Hence, creating a pathway for greener environments.

Boosting Economic

According to an article by Reuters, two Venezuelan engineers, John Naizzir and Albermar Dominguez, turned plastic waste into car parts to help alleviate the country’s economic crisis. With recycled plastic and 3D printing, the two engineers could counter the need and the high price associated with imported car parts by using cheap recycled plastic material to make the same parts.

Increase in availability of raw materials

Recycled plastics have similar properties to virgin plastics and increase the availability of raw materials for the automotive industry. This is not only limited to the automotive industry, as other industries can benefit from them.

Reduction in prices

Although recycled plastic is similar to virgin plastics, they cost lesser. Car companies and other industries will benefit from the price reduction. However, they might require more processing due to the presence of impurities. Nevertheless, industries can still be profitable.

Conclusion

Recycled plastic is very cheap. Hence, their application in the automotive industry for a part and product manufacturing and prototyping. Using the materials, the automotive industry has been able to circumvent and resolve several challenges, such as increased material cost, while ensuring a greener environment. This article discussed how the automotive industry uses recycled plastic for 3D printing automotive parts. Do you want a competitive price for quality 3D-printed car parts? Upload your CAD file and get an instant quote for your design.